When it comes to inventory placement, collaboration is key – including that between humans and machines. Follow these four steps to make machine learning worth the investment.

Spreadsheets, software and even people can get in the way of improving inventory processes.

Software companies promise that machine learning (ML) is the answer, but machine learning without good business processes is a recipe for wasted investment.

But there is a better way, which revolves around four key ideas:

1. Tearing down silos

Inventory placement is controlled by three often disconnected plans:

- The buyers curating the assortment

- The operations team creating the bulk orders

- The replenishers restocking the stores.

This disconnection leads to lost opportunity in regard to inventory levels, inventory turn and end-of-life markdowns.

Making a single plan available to the whole team reduces the opportunity to drop the ball.

2. Embrace collaboration

Having one plan requires all three teams to collaborate and requires tools to facilitate that collaboration in real time.

Some retailers may find it beneficial to merge two of the above roles, considering that a collaborative team is a more efficient team.

3. Creating a living plan

Silos exist because each of the three roles makes inventory decisions in different times and places.

While buyers are focusing on the full lifecycle of a product, replenishers are interested in the day-to-day movement in-store, with operations roles sitting somewhere in the middle.

Business processes must be built around the need to make real-time decisions.

“While buyers are focusing on the full lifecycle of a product, replenishers are interested in the day-to-day movement in-store, with operations roles sitting somewhere in the middle”

Historically, tool capability has constrained this ability – but no more.

Retailers should demand real-time promotion and assortment analysis from their inventory software.

4. Humans are just as important as machines

ML gives us a more detailed way to plan inventory and evaluate changes.

However, some describe ML as if the “M” stands for magic.

Let's be blunt: ML without sound business processes will waste your money.

IDG Retail Insights refers to the combination of ML and human wisdom as “contextual collective intelligence” (CCI).

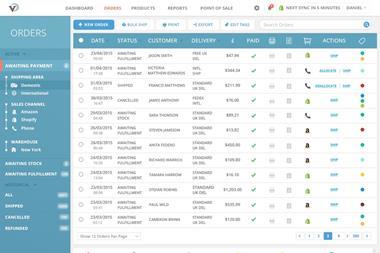

Solutions that are powered by ML provide retail employees with a fast, powerful calculator to forecast and evaluate inventory across merchandising, planning, sales and marketing – in real time to ensure product is bought, promoted and placed for maximum service levels and profitability.

But ML is only that – a calculator.

It needs to be placed in the hands of a business-savvy user and supported by a collaborative planning process.

Only then will you find the key to better inventory placement in stores and fulfilment centres.

Matt Jones is vice-president of industry and solution strategy at Infor Retail

Click here to learn more about Infor Demand Management, powered by machine learning.

No comments yet